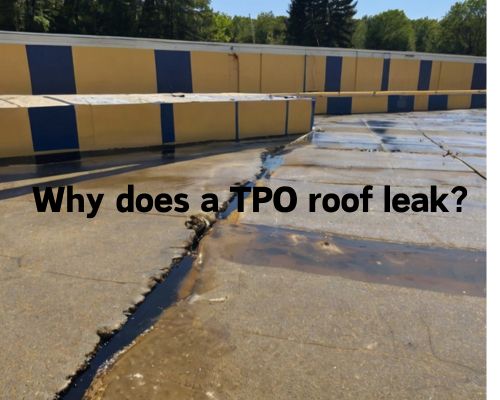

“When it comes to TPO (Thermoplastic Polyolefin) roofs, several factors can cause leaks. One leading cause is improper installation. Seams not correctly sealed can allow water infiltration. Damage from foot traffic or wind-blown debris can also puncture the membrane, leading to leaks if not promptly addressed.” said Charles Jimerson from CJ Commercial Roofing NJ.

Another common issue is age-related wear and tear. Over time, the TPO material can degrade, making it more susceptible to punctures and tears.

Regular maintenance and inspections are crucial to identify and repair these vulnerabilities before they become significant problems.

Maintaining a clean roof surface is essential. Dirt and debris can trap moisture, promoting membrane degradation and increasing the risk of leaks.

Additionally, ensuring gutters and drainage systems are functioning correctly can prevent water accumulation that might otherwise exploit weaknesses in the roofing system.

By staying proactive, you can extend the life of your TPO roof and keep it leak-free.

Anatomy of a TPO Roofing System

A TPO roofing system is composed of various key elements that contribute to its functionality and durability. Understanding each component and the factors influencing its longevity helps in ensuring optimal performance.

Components and Installation

A TPO roofing system is primarily made up of single-ply membranes and multiple supporting layers.

Key Components:

- TPO Membrane: The main component, available in various thicknesses (40-mil to 80-mil), typically used on flat or low-slope roofs.

- Insulation: Provides a solid substrate and improves energy efficiency.

- Adhesive: Bonds the membrane to the substrate.

- Seams: Joined using heat welding to ensure a watertight seal.

- Cover Board and Underlayment: Additional layers enhancing stability and protection.

- Metal Roof Deck: Acts as the primary structural support.

Installation Process:

- Prepare the roof deck.

- Install the cover board and underlayment.

- Secure the insulation.

- Adhere the TPO membrane using adhesive.

- Weld the seams using specialized equipment.

For a secure and quality installation, see Charles Jimerson from CJ Commercial Roofing NJ.

Factors Affecting Durability and Longevity

Several factors influence the lifespan and durability of a TPO roofing system:

- Foot Traffic: Excessive foot traffic can lead to wear and tear.

- UV Rays: Continuous exposure can degrade the membrane over time.

- Thermal Expansion: The TPO membrane must accommodate expansions and contractions caused by temperature fluctuations.

- Proper Installation: Ensuring all components are correctly installed and seams are properly welded is crucial for durability.

- Maintenance: Regular inspections and timely repairs help in prolonging the roof’s lifespan.

Common TPO Roofing Issues and Maintenance

TPO roofing systems, known for their durability and energy efficiency, can encounter several issues. Regular maintenance and prompt repairs are crucial to extend the life of the roof and maintain its performance.

Identifying and Repairing Leaks

Leaks are a significant concern for TPO roofs. Common causes include punctures, tears, and seam failures.

Foot traffic, falling debris, and sharp objects like nails can easily damage the membrane. You should monitor for signs of bubbling, ponding water, and visible damage.

To repair leaks, inspect the roof regularly for visible damage. Small punctures and tears can often be repaired using TPO patch kits.

For larger issues like tears or seam failures, it’s best to contact a roofing contractor. Always ensure that repairs comply with local building codes for safety and performance.

Preventive Strategies and Best Practices

A key strategy for TPO roof maintenance is regular inspections. Schedule inspections at least twice a year and after extreme weather events.

Keep the roof clean by removing dirt, debris, and grime. Clean gutters and drainage systems to prevent water pooling. This can lead to adhesion problems and leaks.

Focus on addressing wear and tear from extreme temperatures. If signs of damage appear, act promptly to prevent larger issues.

Ensure that a professional properly installs your TPO roofing system. This helps prevent initial installation errors that could lead to future problems.

By implementing these best practices, you can maintain your TPO roof’s durability and energy efficiency.